Are you looking for an answer to the topic “How can we prevent galvanic corrosion between aluminum and zinc?“? We answer all your questions at the website Chiangmaiplaces.net in category: +100 Marketing Blog Post Topics & Ideas. You will find the answer right below.

The most common way to do this is to mount an anode of a less noble material (often zinc) in direct metallic contact with the aluminium object to be protected. By doing this, you sacrifice the less noble material – it corrodes – for the aluminium. We call it a sacrificial anode.In the case of zinc and aluminum, there is only a slight chance of a reaction because of the relatively small change in potential between the two metals and the formation of an insulating film on the surface of the aluminum. One of the key factors in the reaction between dissimilar metals is the contact surface area.Galvanic corrosion can also be avoided by minimizing the potential difference between the metals. As mentioned previously, the electrons flow from the anode to the cathode due to the potential difference, which acts as the driving force.

Table of Contents

Can you put aluminum and zinc together?

In the case of zinc and aluminum, there is only a slight chance of a reaction because of the relatively small change in potential between the two metals and the formation of an insulating film on the surface of the aluminum. One of the key factors in the reaction between dissimilar metals is the contact surface area.

How can galvanic corrosion be reduced or eliminated?

Galvanic corrosion can also be avoided by minimizing the potential difference between the metals. As mentioned previously, the electrons flow from the anode to the cathode due to the potential difference, which acts as the driving force.

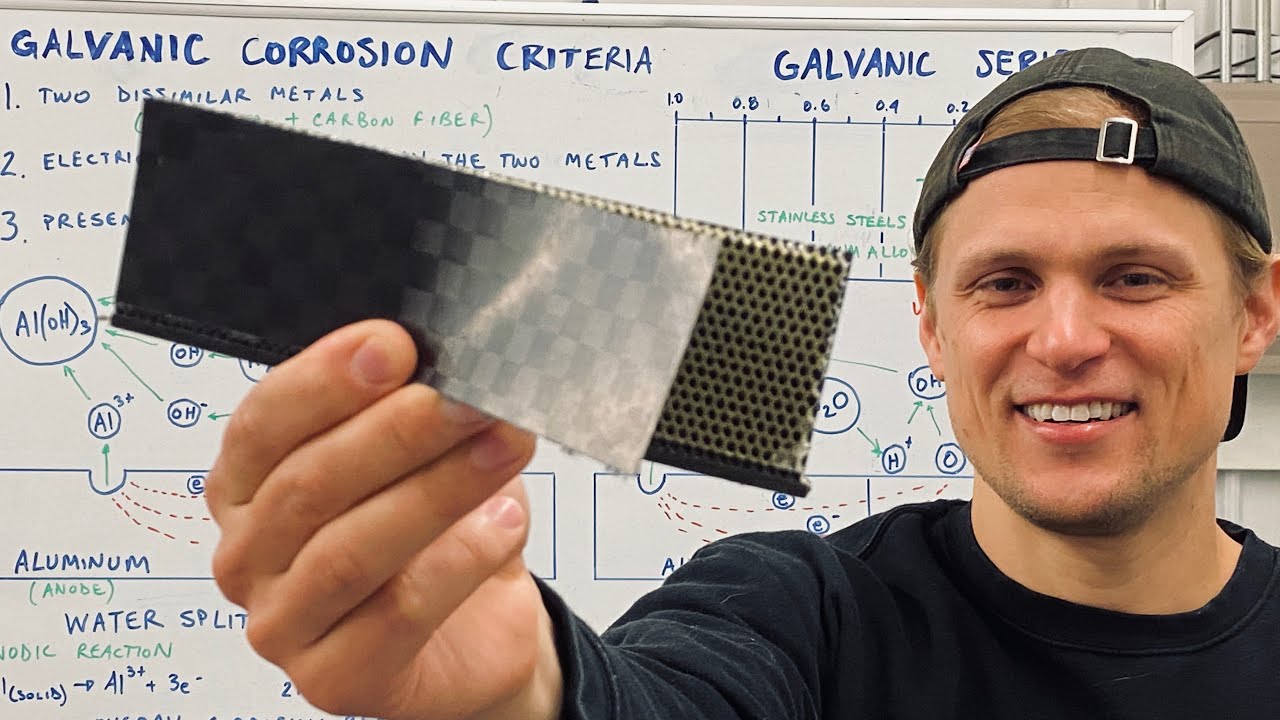

GALVANIC CORROSION: CARBON FIBER + ALUMINUM | What is it? How we prevent it on the DarkAero 1!

Images related to the topicGALVANIC CORROSION: CARBON FIBER + ALUMINUM | What is it? How we prevent it on the DarkAero 1!

What can I use to stop aluminum & steel corrosion where they join together?

Plastic or rubber washers or gaskets are good suggestions. Along with corrosion, discoloration of stainless steel may occur when combined with aluminum.

How can we protect dissimilar metals?

One way to protect dissimilar metals without adding large nonmetallic barriers is to galvanize metal. During the galvanization process, you add a layer of zinc to a base metal in order to add corrosion resistance.

How do you protect aluminum from galvanic corrosion?

The most common way to do this is to mount an anode of a less noble material (often zinc) in direct metallic contact with the aluminium object to be protected. By doing this, you sacrifice the less noble material – it corrodes – for the aluminium.

Why do zinc and aluminium do not corrode?

Solution : Aluminium and zinc react with moist air to form a thin protective layer of oxide on their surfaces. This layer prevents further corrosion of the metals.

How can we prevent galvanic corrosion between dissimilar metals?

- Selecting materials with similar corrosion potentials.

- Breaking the electrical connection by insulating the two metals from each other.

- Applying coatings to both materials. …

- Separating the two materials by inserting a suitably sized spacer.

See some more details on the topic How can we prevent galvanic corrosion between aluminum and zinc? here:

Galvanic Corrosion: A Guide for Architecture

For instance, aluminum is close to zinc on the galvanic series, so it won’t exhibit much corrosion. Finally, to completely stop corrosion, …

Zinc and Dissimilar Metals in Contact – American Galvanizers …

Generally, severity of corrosion increases when combining galvanized steel with metals far away from zinc in the galvanic series. Actual electrical potential …

Three ways to prevent Galvanic Corrosion – LinkedIn

KEEP THAT WATER OUT. No water, no electrolyte, no galvanic corrosion. · Insulate dissimilar materials, i.e., break the electrical continuity …

Galvanic Action Corrosion Prevention | Architect’s Blog

Aluminum is very susceptible to galvanic corrosion in contact with copper, with an electrolyte like water with some ionic content. One can tin …

How can corrosion be prevented?

- Use non-corrosive metals, such as stainless steel or aluminium.

- Make sure the metal surface stays clean and dry.

- Use drying agents.

- Use a coating or barrier product such as grease, oil, paint or carbon fibre coating.

- Lay a layer of backfill, for example limestone, with underground piping.

What are the different methods of preventing corrosion?

- BARRIER COATINGS. One of the easiest and cheapest ways to prevent corrosion is to use barrier coatings like paint, plastic, or powder. …

- HOT-DIP GALVANIZATION. …

- ALLOYED STEEL (STAINLESS) …

- CATHODIC PROTECTION. …

- EONCOAT – A NEW WAY TO PROTECT ASSETS FROM CORROSION.

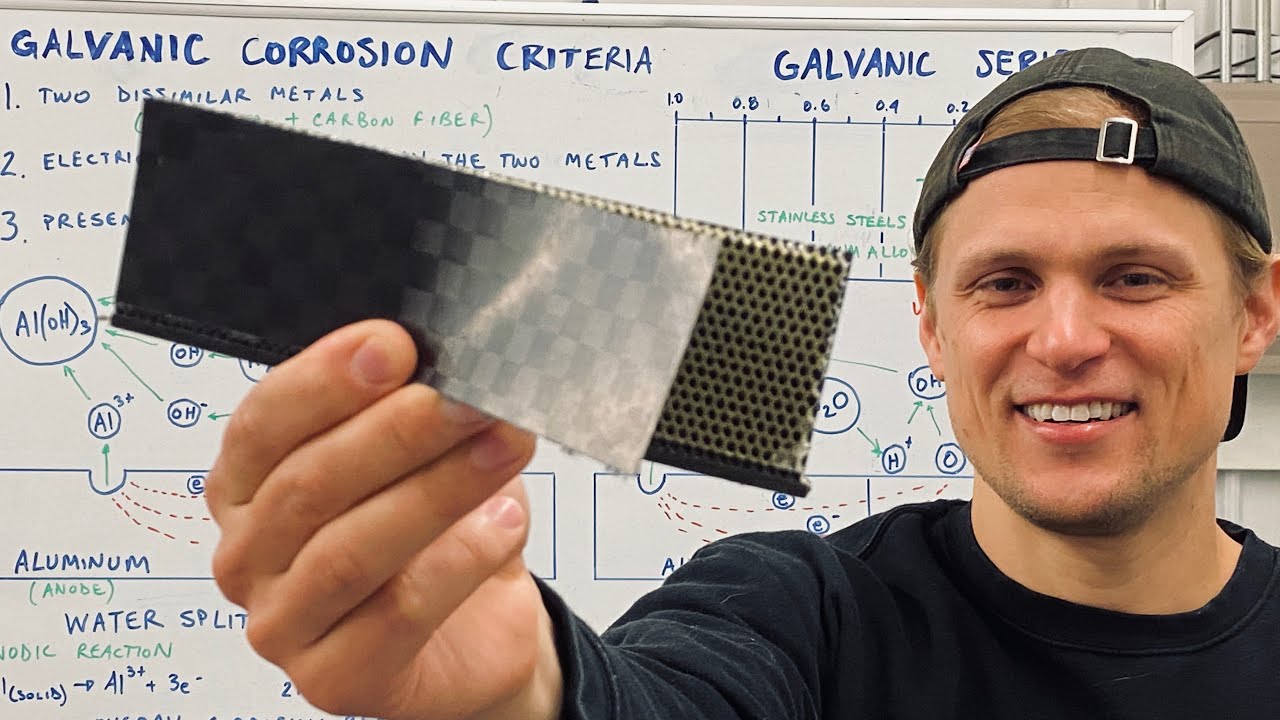

30 – Galvanic corrosion

Images related to the topic30 – Galvanic corrosion

Can galvanized steel and aluminum touch?

Aluminum. When used in mild-to-moderately corrosive environments and/or mild-to-moderate humidity, contact between a galvanized surface and aluminum is unlikely to cause substantial incremental corrosion.

Does paint prevent galvanic corrosion?

In addition to providing barrier protection to materials, paint can also reduce exposure to an electrolyte and slow down galvanic cell corrosion. As a result of holidays and chips in the coating, the anode will have a very small surface area exposed to the electrolyte solution.

Can you use stainless bolts on aluminum?

While many people worry that stainless steel fasteners, such as screws, bolts, nuts, or host of other options, won’t work with aluminum due to the risk of galvanic corrosion between the two very different metals, the truth is that stainless steel is the metal of choice for fasteners to secure your aluminum materials.

How is galvanic corrosion controlled?

Galvanic Corrosion Prevention

Galvanic corrosion can be prevented through a number of methods: Select metals/alloys as close together as possible in the galvanic series. Avoid unfavorable area effect of a small anode and large cathode. Insulate dissimilar metals wherever practical.

Does zinc coating prevent galvanic corrosion?

Interestingly, another reason that zinc coating is so effective at stopping corrosion is due to zinc’s own corrosive properties. Through a process known as galvanic corrosion, zinc will “defer” to the metal that it’s protecting. Zinc is more electrochemically active than iron.

Does zinc plated steel react with aluminum?

Galvanized steel screws, however, are plated with a corrosion-resistant coating, usually consisting of zinc, that is not nearly as reactive with aluminum. The zinc plating prevents the underlying steel from coming into contact with the aluminum, and the risk of corrosion of the aluminum is reduced significantly.

What is galvanic corrosion protection?

Galvanic cathodic protection is an corrosion prevention method that uses electrochemical means to protect a base material from corrosion. It does this through the use of a sacrificial anode that corrodes before the material being protected by the sacrificial anode.

Does anodizing aluminum prevent galvanic corrosion?

Anodized aluminum is one way to break the circuit and thus prevent galvanic corrosion. When you anodize aluminum, it forms a thick coating made up of aluminum oxide. This protective layer is a thousand times thicker than aluminum’s natural oxide.

How to prevent galvanic corrosion in carbon composites

Images related to the topicHow to prevent galvanic corrosion in carbon composites

Why does zinc not rust?

Like aluminum, zinc is highly reactive to oxygen in the presence of moisture, and the coating prevents the iron in the steel from further oxidation. Industrial Metal Supply carries a wide range of rust-resistant metals for a variety of applications.

Why is carbon not used for reducing aluminium from Aluminium oxide?

Because aluminium has greater affinity for oxygen than for carbon, therefore carbon cannot reduce alumina (Al2O3) to aluminium.

Related searches to How can we prevent galvanic corrosion between aluminum and zinc?

- galvanic corrosion chart

- how to prevent galvanic corrosion between aluminum and galvanized steel

- how to prevent galvanic corrosion between copper and steel

- how to prevent galvanic corrosion between aluminum and titanium

- how to prevent galvanic corrosion between aluminum and brass

- how to prevent galvanic corrosion between aluminum and copper

- barrier between aluminum and steel

- preventing galvanic corrosion between aluminum and steel

Information related to the topic How can we prevent galvanic corrosion between aluminum and zinc?

Here are the search results of the thread How can we prevent galvanic corrosion between aluminum and zinc? from Bing. You can read more if you want.

You have just come across an article on the topic How can we prevent galvanic corrosion between aluminum and zinc?. If you found this article useful, please share it. Thank you very much.