Are you looking for an answer to the topic “How is galvanic corrosion prevented?“? We answer all your questions at the website Chiangmaiplaces.net in category: +100 Marketing Blog Post Topics & Ideas. You will find the answer right below.

Galvanic corrosion can be prevented by: Selecting materials with similar corrosion potentials. Breaking the electrical connection by insulating the two metals from each other. Applying coatings to both materials.When using stainless steel fasteners with aluminum surfaces, you can prevent corrosion by placing something between the two metals. Plastic or rubber washers or gaskets are good suggestions. Along with corrosion, discoloration of stainless steel may occur when combined with aluminum. This is also called ‘tea staining’.It is generally done by dipping iron in molten zinc. The zinc layer coating thus protects the iron from corrosion. Providing a layer of paint or grease on the metal can prevent the exposure of the metal with the external environment thereby preventing corrosion.

- Insulating dissimilar materials using non-conductive material coatings, greases, paints, treatments, or primers. …

- Using buffers — such as pipe wraps, clamp liners, and wear pads — between dissimilar metals to eliminate galvanic cell creation and interrupt electrical paths.

Table of Contents

How can we prevent galvanic corrosion between aluminum and stainless steel?

When using stainless steel fasteners with aluminum surfaces, you can prevent corrosion by placing something between the two metals. Plastic or rubber washers or gaskets are good suggestions. Along with corrosion, discoloration of stainless steel may occur when combined with aluminum. This is also called ‘tea staining’.

How is corrosion prevented?

It is generally done by dipping iron in molten zinc. The zinc layer coating thus protects the iron from corrosion. Providing a layer of paint or grease on the metal can prevent the exposure of the metal with the external environment thereby preventing corrosion.

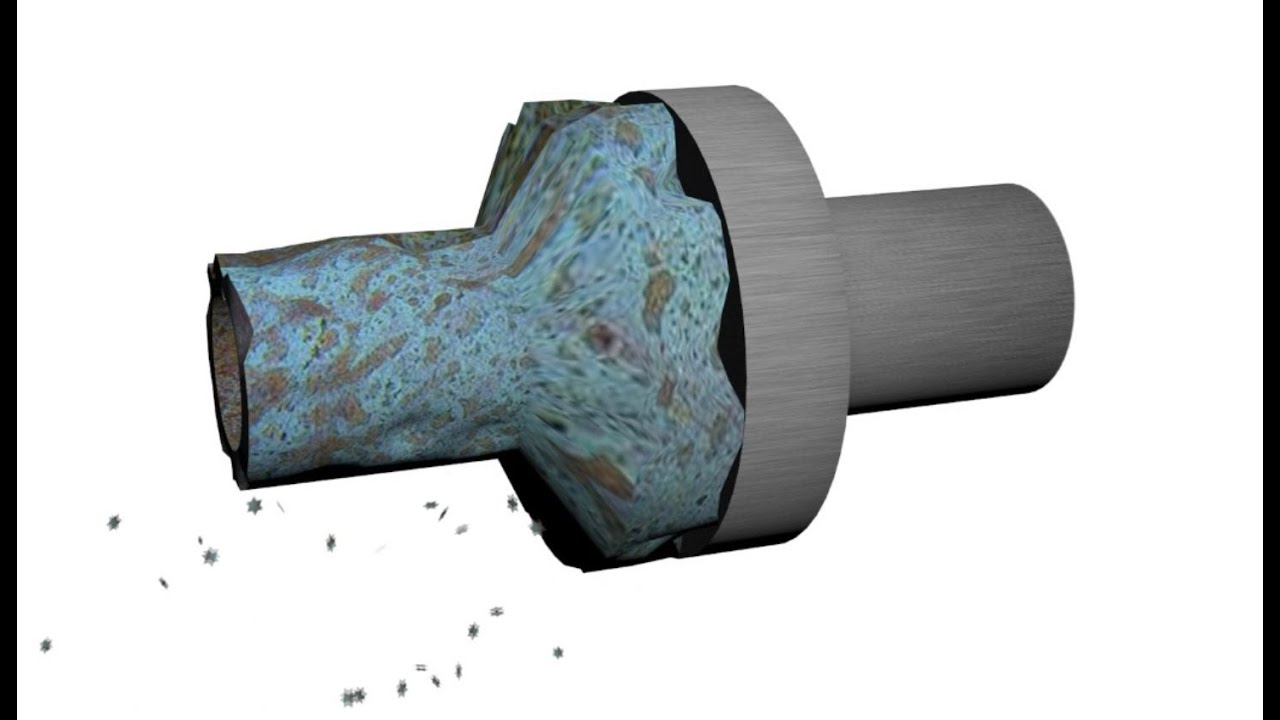

Galvanic Corrosion | Forms of Corrosion

Images related to the topicGalvanic Corrosion | Forms of Corrosion

How can we prevent galvanic corrosion between pipe and support?

- Insulating dissimilar materials using non-conductive material coatings, greases, paints, treatments, or primers. …

- Using buffers — such as pipe wraps, clamp liners, and wear pads — between dissimilar metals to eliminate galvanic cell creation and interrupt electrical paths.

How do you protect aluminum from galvanic corrosion?

The most common way to do this is to mount an anode of a less noble material (often zinc) in direct metallic contact with the aluminium object to be protected. By doing this, you sacrifice the less noble material – it corrodes – for the aluminium.

Which method is most suitable for preventing galvanic corrosion?

- Selecting materials with similar corrosion potentials.

- Breaking the electrical connection by insulating the two metals from each other.

- Applying coatings to both materials. …

- Separating the two materials by inserting a suitably sized spacer.

Will Grease prevent galvanic corrosion?

In the atmosphere, galvanic corrosion is generated by an entry of rain water in outdoor use and under high humidity. If the contact surface is protected by oils and fats such as oil and grease, however, galvanic corrosion is greatly inhibited.

What is done to prevent the corrosion of metals?

Applying a protective coating over the metal surface: Applying a paint coating is a cost-effective way to prevent corrosion. The paint coating act as a barrier between the metal surface and atmospheric moisture to avoid its contact and prevent corrosion. Another alternative is to apply a powder coating.

See some more details on the topic How is galvanic corrosion prevented? here:

5 Ways to Avoid Galvanic Corrosion – Corrosionpedia

Therefore, measures that involve isolating the contacting metals and the electrolyte can prove to be effective in preventing galvanic corrosion.

Avoiding galvanic corrosion – Shapes by Hydro

Avoiding galvanic corrosion · Where there is contact with a more noble metal, such as copper and carbon steel. After magnesium and zinc, …

How To Avoid And Prevent Galvanic Corrosion – Marsh …

To minimize the risk of galvanic corrosion of fasteners, match the surface metal on the fastener with that on the metal it will fasten.

Galvanic Corrosion: Avoidance and Risk Mitigation Explained

Options to Reduce Galvanic Corrosion Risk · Insulating dissimilar materials using non-conductive material coatings, greases, paints, treatments, or primers.

How can we prevent corrosion and rusting?

- Use an Alloy. Many outdoor structures, like this bridge, are made from COR-TEN steel to reduce the effects of rust. …

- Apply Oil. …

- Apply a Dry Coating. …

- Paint the Metal. …

- Start Resolving Your Industrial Rust Now. …

- Store Properly. …

- Galvanize. …

- Blueing.

Which of the following is Main corrosion prevention method?

1. Which of the following method is adopted for preventing corrosion by acids? Explanation: Neutralisation with lime is done for preventing corrosion by acids.

How can we prevent galvanic corrosion between copper and galvanized steel?

The most common ways to prevent galvanic corrosion include: Electrically insulate the dissimilar metals using a brass nipple or other dielectric fitting (plastic in some applications) between the materials.

How do I protect my pipes from corrosion?

Protective linings or special coatings can prevent corrosion in pipes as well as other surfaces. That includes things such as beams, joints, and bolts. For instance, galvanization works by adding a layer of zinc to metallic surfaces such as steel or iron.

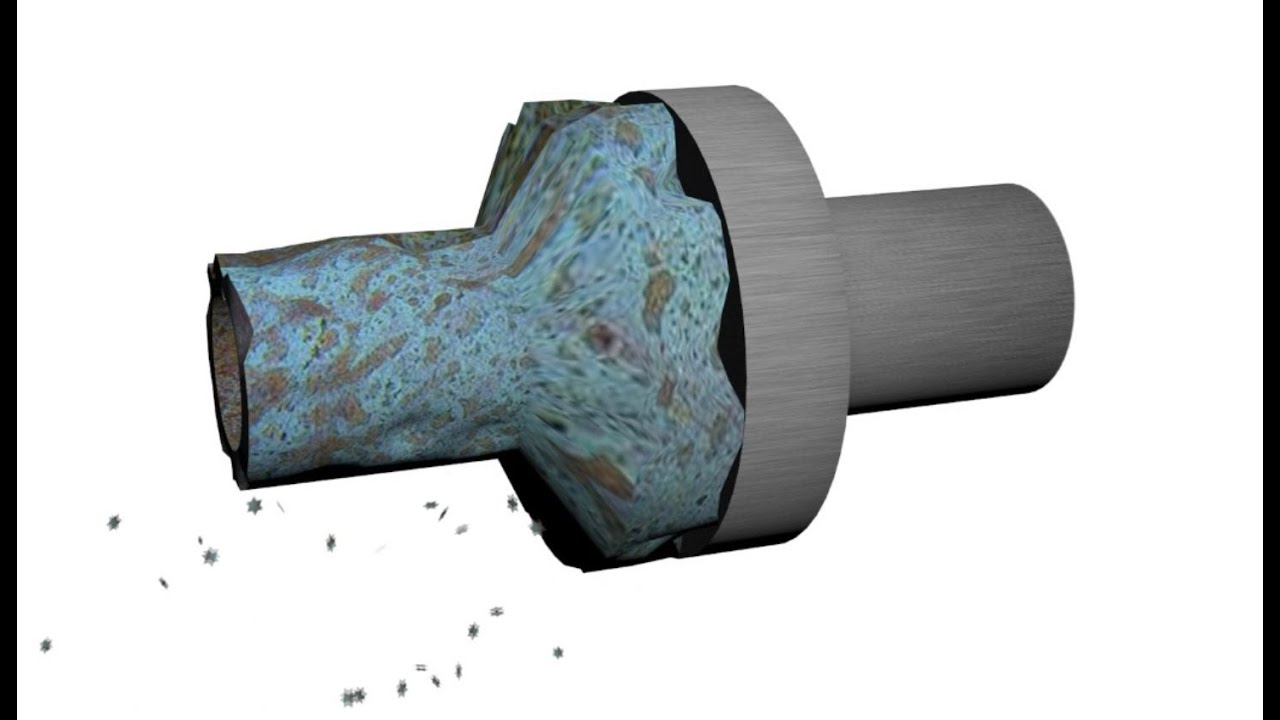

How to Prevent Galvanic Corrosion | Chomerics

Images related to the topicHow to Prevent Galvanic Corrosion | Chomerics

Does stainless steel prevent galvanic corrosion?

The combination of aluminum and stainless steel causes galvanic corrosion.

Does zinc coating prevent galvanic corrosion?

Interestingly, another reason that zinc coating is so effective at stopping corrosion is due to zinc’s own corrosive properties. Through a process known as galvanic corrosion, zinc will “defer” to the metal that it’s protecting. Zinc is more electrochemically active than iron.

Does anodizing prevent galvanic corrosion?

Anodized aluminum is one way to break the circuit and thus prevent galvanic corrosion. When you anodize aluminum, it forms a thick coating made up of aluminum oxide. This protective layer is a thousand times thicker than aluminum’s natural oxide.

How can we prevent galvanic corrosion between copper and aluminum?

Aluminum is very susceptible to galvanic corrosion in contact with copper, with an electrolyte like water with some ionic content. One can tin plate the copper bolts, for instance, to help stop or slow the galvanic attack.

What are the three keys to corrosion prevention?

We have learned that three things are required for the anodic and cathodic steps of corrosion to occur: an electrolyte, an exposed metal surface, and an electron acceptor. It follows, then, that we can prevent corrosion by removing one of these essential conditions.

What causes galvanic corrosion?

Galvanic corrosion (also called ‘ dissimilar metal corrosion’ or wrongly ‘electrolysis’) refers to corrosion damage induced when two dissimilar materials are coupled in a corrosive electrolyte. It occurs when two (or more) dissimilar metals are brought into electrical contact under water.

Will silicone grease prevent galvanic corrosion?

“Tests show that both Dursan® and Silcolloy® are effective in minimizing galvanic corrosion between aluminum 6061 and 304 stainless steel (Dursan better than Silcolloy). This is evidenced by the much reduced galvanic current (indicating corrosion rate) with coatings.”

What happens when you put aluminum and copper together?

Aluminum will be very susceptible to galvanic corrosion in contact with copper, assuming that the two metals are also in contact with a common electrolyte (such as water with some ionic content.)

Does dielectric grease prevent rust?

Pros of Dielectric Grease

One of its major advantages is providing a seal on metal surfaces. When the grease is applied to metal parts of the electrical system, it protects them from rusting and corrosion.

Safeshore guide to galvanic corrosion galvanic isolation

Images related to the topicSafeshore guide to galvanic corrosion galvanic isolation

How can corrosion be prevented Shaalaa?

One simple way to prevent corrosion is to use a corrosion-resistant metal such as aluminium or stainless steel. Depending on the application, these metals can be used to reduce the need for additional corrosion protection.

What are the three methods of preventing rusting of iron?

Solution : The rusting of iron can be prevented by painting, oiling, greasing or varnishing its surface. <br> (2) Galvanisation is another method of protecting iron from rusting by coating iron with a thin layer of zinc. <br> (3) Corrosion of iron is prevented by coating iron with non-xcorrosive substance like carbon.

Related searches to How is galvanic corrosion prevented?

- galvanic corrosion chart

- galvanic corrosion can be prevented by

- how does galvanic corrosion work

- how to prevent galvanic corrosion between copper and steel

- coating to prevent galvanic corrosion

- how to treat galvanic corrosion

- how to prevent galvanic corrosion between aluminum and brass

- what causes galvanic corrosion

- how is galvanic corrosion prevented

- how is corrosion prevented

- how to prevent galvanic corrosion between aluminum and copper

- is galvanic corrosion dangerous

- why does galvanic corrosion occur

- how to prevent galvanic corrosion between aluminum and steel

- why is galvanic corrosion a problem

Information related to the topic How is galvanic corrosion prevented?

Here are the search results of the thread How is galvanic corrosion prevented? from Bing. You can read more if you want.

You have just come across an article on the topic How is galvanic corrosion prevented?. If you found this article useful, please share it. Thank you very much.