Are you looking for an answer to the topic “How strong is spot welding?“? We answer all your questions at the website Chiangmaiplaces.net in category: +100 Marketing Blog Post Topics & Ideas. You will find the answer right below.

The test, In this case, illustrated that the spot weld had an Ultimate Tensile Strength of 3261Kg compared to 1294Kg for an 8mm MIG plug weld.This weld has a shear strength of 1100 lbs. (499.5kg) less than the fully penetrated weld. For a full penetrating spot weld on a given plate thickness, the area of the interface will depend to a large extent on the shielding gas and the arc voltage.Spot welding can also be difficult due to various factors. The most common ones include using galvanized steel and aluminum. These materials require high electric current levels to weld and a longer welding time, unlike welding steel. The other factor is the inappropriate thickness of the welding materials.

- Only thin metals can be welded accurately and efficiently.

- Installment cost is more.

- This type of welding gets deformed.

- Changes in power supply leads to weak welding.

Table of Contents

What is the strength of a spot weld?

This weld has a shear strength of 1100 lbs. (499.5kg) less than the fully penetrated weld. For a full penetrating spot weld on a given plate thickness, the area of the interface will depend to a large extent on the shielding gas and the arc voltage.

Is spot welding hard?

Spot welding can also be difficult due to various factors. The most common ones include using galvanized steel and aluminum. These materials require high electric current levels to weld and a longer welding time, unlike welding steel. The other factor is the inappropriate thickness of the welding materials.

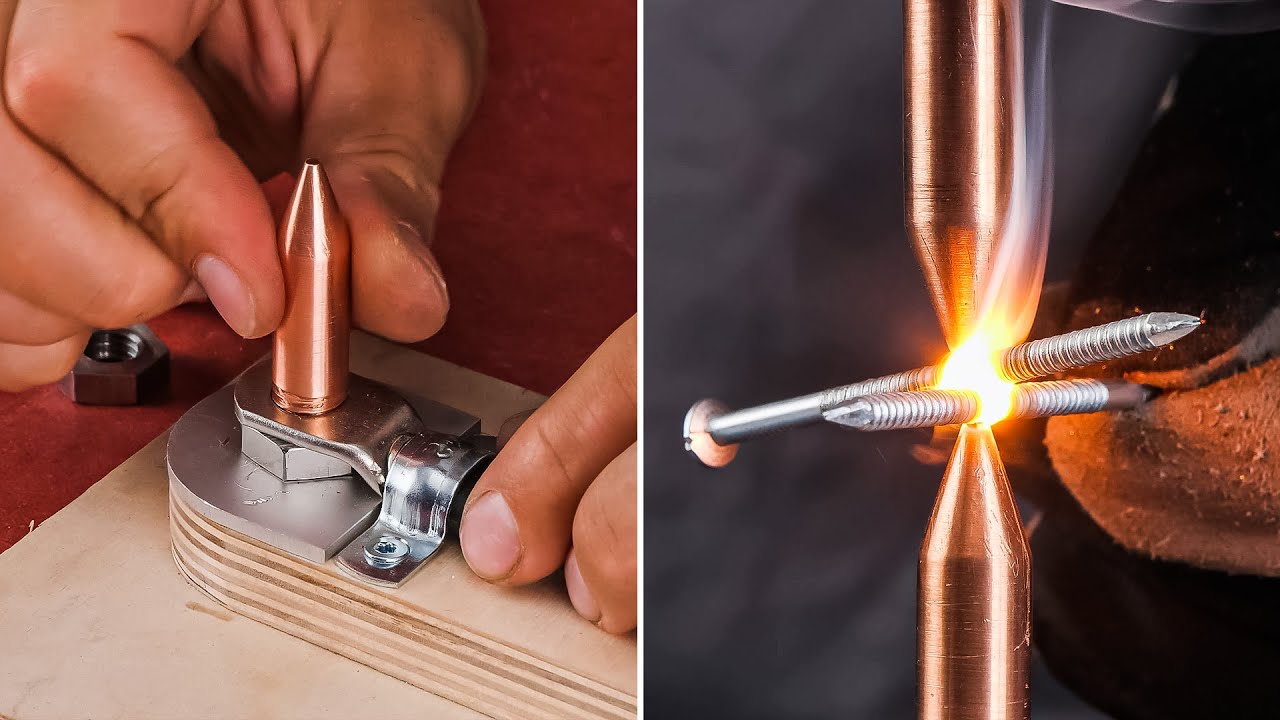

Resistance Spot Welding – How It Works

Images related to the topicResistance Spot Welding – How It Works

What are the disadvantages of spot welding?

- Only thin metals can be welded accurately and efficiently.

- Installment cost is more.

- This type of welding gets deformed.

- Changes in power supply leads to weak welding.

Can a spot welder shock you?

Can I get electrocuted by touching the weld cables or electrodes? – Luckily, No. For all concerned, the voltage for all resistance welding technologies is below the level where there would be a concern about electric shock. This includes CD, AC, DC, and HF models.

How thick can you spot weld?

Spot welding is primarily used for joining parts that are normally up to 3 mm in thickness. Thickness of the parts to be welded should be equal or the ratio of thickness should be less than 3:1. The strength of the joint depends on the number and size of the welds. Spot-weld diameters range from 3 mm to 12.5 mm.

Is spot welding easy?

Spot welding is among the earliest welding procedures and is very well-known and easy to do for even beginner welders. The procedure is totally defined and readily applies to a lot of thin metals like stainless steel, nickel alloys and titanium.

What type of welding is strongest?

TIG welding is often considered the strongest weld since it produces extreme heat, and the slow cooling rate results in high tensile strength and ductility. MIG is also an excellent candidate for the strongest type of weld because it can create a strong joint.

See some more details on the topic How strong is spot welding? here:

Disadvantages & Advantages of Spot Welding – Sciencing

Spot welding is quick and easy. There is no need to use any fluxes or filler metal to create a join by spot welding, and there is no dangerous …

Spot welding – Wikipedia

Typically the sheets are in the 0.5 to 3 mm (0.020 to 0.118 in) thickness range. Forcing a large current through the spot will melt the metal and form the weld.

Mig Spot Welding – shear strength – ESAB

Notice that one weld is less penetrated and contains less nugget cross-sectional area at the interface. This weld has a shear strength of 1100 lbs. (499.5kg) …

What is Spot Welding? Understanding it Thoroughly – Water …

The welding guns used in spot welding are heavy and require great strength when using them. Such characteristics make the method very dangerous, …

How long does it take to weld one spot?

Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds).

How long does it take to spot weld?

Spot welding is also a fast welding process. According to Wikipedia, the average weld time for spot welding is just 0.01 to 0.63 seconds. Like with other welding processes, the weld time varies depending on the thickness of the workpieces. Thicker workpieces tend to have a longer weld time than thinner workpieces.

Are spot welds weak?

Joining two pieces of metal together by spot welding can be quick and efficient, but the resulting join will not be adequate for all purposes. It can be weak or deformed, particularly if the method is not used correctly.

Does spot welding need gas?

MIG welding uses a shielding gas to protect the weld from contamination. The most common type of gas used is carbon dioxide and argon but you can also use helium in addition. Spot welding does not use any gas during the welding process.

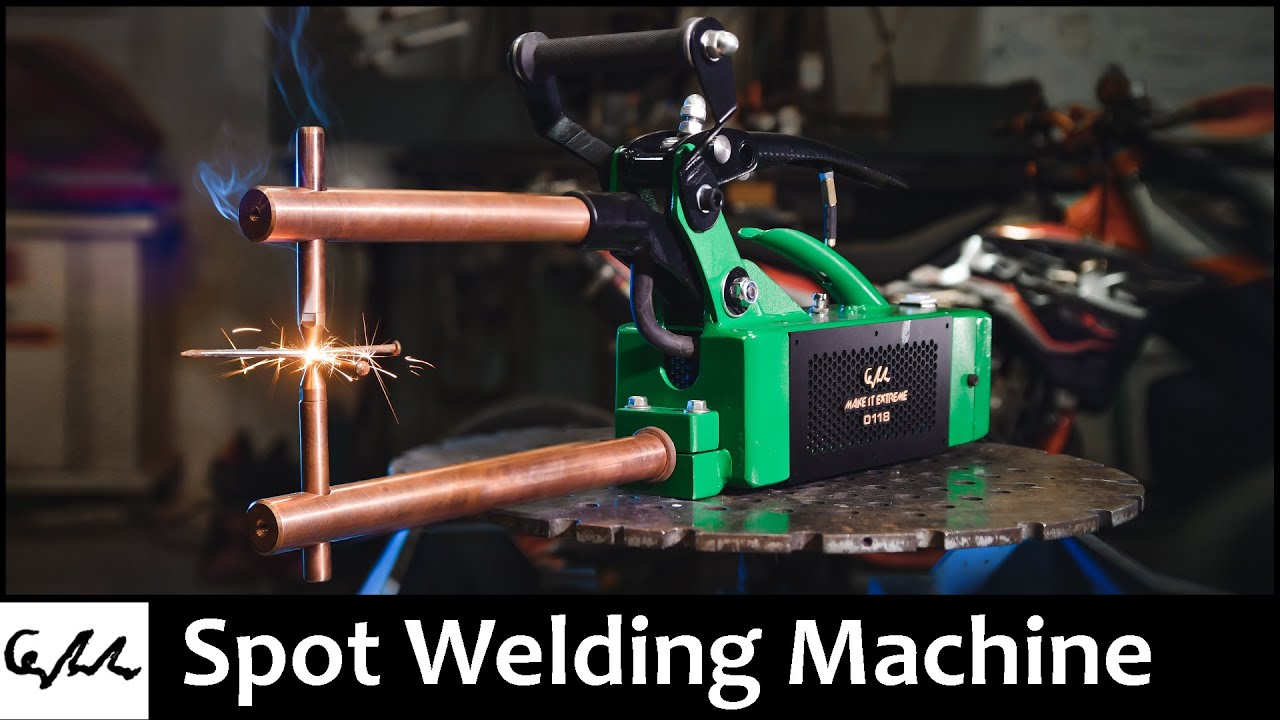

Making a Spot welding machine | @Make it Extreme

Images related to the topicMaking a Spot welding machine | @Make it Extreme

What would you use a spot welder for?

Spot welding (also known as resistance spot welding) is a resistance welding process. This welding process is used primarily for welding two or more metal sheets together by applying pressure and heat from an electric current to the weld area.

Can you touch what you are welding?

You should never touch a welding rod with one hand while touching the metal being welded with your other hand. However, you can touch your electrode on purpose if you want to have easier starts or heat treat material by applying heat through an electrode.

Can you hold the stick when welding?

You can hold the electrode when stick welding (SMAW) for a short time to improve the electrode’s stability when striking the arc or making a few tack welds. When doing so, you must wear dry welding gloves in good condition.

Are Spot Welders AC or DC?

It is tried and true. AC is more robust with longer life and is more familiar to many facilities. If you use press welders, power is not an issue and work with normal quality standards AC is a good choice. If the facility already has many other AC units for backup AC would be a very good choice.

What metals can you spot weld?

Copper can be spot welded. But not surprisingly, the standard spot welding copper electrodes do not work. Molybdenum and tungsten electrodes are the primary choices for spot welding copper. These metals have high electrical resistance and melting temperatures.

Is TIG welding the same as spot welding?

…

Spot Welding vs. TIG/MIG Welding.

| Factors | Resistance Spot Welding | TIG / MIG Welding |

|---|---|---|

| Size of weld | Small | Varies |

| Material distortion | Minimal to none | Minimal to Extreme |

Is spot welding hot work?

SPOT WELDING can cause fire or explosion. Sparks can fly off from the welding arc. The flying sparks, hot workpiece, and hot equipment can cause fires and burns. Accidental contact of elec- trode to metal objects can cause sparks, explosion, overheating, or fire.

Can you spot weld wire?

1. Spot/Resistance Welding? Spot welding, also referred to as resistance welding, is the process in which an electrical current is used to generate heat and bond the desired material. Most of the time, spot welding is used when a single layer of wire mesh needs to be joined to itself.

Which welding is the hardest?

TIG welding is the hardest form of welding to learn for a variety of reasons. The process of TIG welding is slow and takes time to get used to as a beginner. A TIG welder requires a foot pedal to feed the electrode and control the variable amperage while maintaining a steady hand at the welding torch.

How to Build a Spot Welder out of an Old Microwave | Remake Project

Images related to the topicHow to Build a Spot Welder out of an Old Microwave | Remake Project

How much weight can a weld hold?

The answer of 927 pounds per 1/16 leg per inch of weld length is the correct answer. The other part of the problem is that you can’t exceed 0.4 times the yield strength of the base metal times the area of the weld (i.e., leg X length). You use the lesser of the two values as the allowable load per ASD.

What is the weakest point of a weld?

The toe of the weld is often the “weakest link” in a weld. This is due mainly to geometry and subsequent stress concentrations. The stress at the toe of a weld can be made greater or lesser through welding technique and proper application of acceptance standards (eliminating undercut, limiting reinforcement, etc.).

Related searches to How strong is spot welding?

- resistance spot welding

- disadvantages of spot welding

- how strong is spot welding

- what is spot welding used for

- spot welding machine

- spot welding parameters

- how to check spot welding strength

- is spot welding easy

- how does a spot weld work

- types of spot welding

- how much weight can a spot weld hold

- spot welding current and voltage

- spot welding advantages and disadvantages

- how much does spot welding cost

Information related to the topic How strong is spot welding?

Here are the search results of the thread How strong is spot welding? from Bing. You can read more if you want.

You have just come across an article on the topic How strong is spot welding?. If you found this article useful, please share it. Thank you very much.